Call Us

+8618553215827- Home Page

- Company Profile

-

Our Products

- Turbo Blower

- Magnetic levitation high speed centrifugal turbo blowers of guaranteed quality for many industries

- High Speed Industrial Energy Saving Wholesale Price Air Suspension Centrifugal TURBO Blower

- Turbo Blower

- Turbo Blower Air Foil Bearing Turbo Blower

- Air foil bearing turbo blower air suspension bearing turbo blower

- High efficiency filter for Huadong turbo blower

- Magnetic bearing turbo blower magnetic suspension bearing turbo blower

- Air Bearing Turbo Blower

- Maglev Suspension Levitation Magnetic Bearing Turbo Blower

- Air suspension turbine vacuum pump

- Maglev High-speed Turbo Air Compressor

- Magnetic suspension turbine vacuum pump

- MVR Steam Compressor

- Industrial use MVR Steam Compressor

- MVR Vapour Blower

- Roots MVR Steam Compressor

- Stainless Steel MVR Blower

- Roots Blower Steam Compressor for MVR system

- MVR Blower for Steam Compression

- MVR Steam Compressor

- MVR Blower Steam Compressor

- MVR Vapor Steam Compressor

- Steam Compressor

- MVR Steam Blower

- Roots Compressor Blower for MVR

- Mechanical Steam Compressor

- MVR Roots Vapor Compressor

- MVR Steam Compressor with Stainless Material SS304

- Roots type MVR Vapour Blower

- Roots Air Blower

- Gas Blower

- Vacuum Roots Blower

- Roots blower

- HDL 2 Lobe Roots Blower

- High Pressure Industrial huadon Series Roots Blower Cement chemical Aeration Sewage Treatment Roots Blower

- HG 3 Lobe Roots Blower

- High efficiency industrial 3 lobe roots blower for sewage treatment pneumatic conveying factory directly sell

- Air cooling structure high efficiency compact HG series 3 lobe roots blower

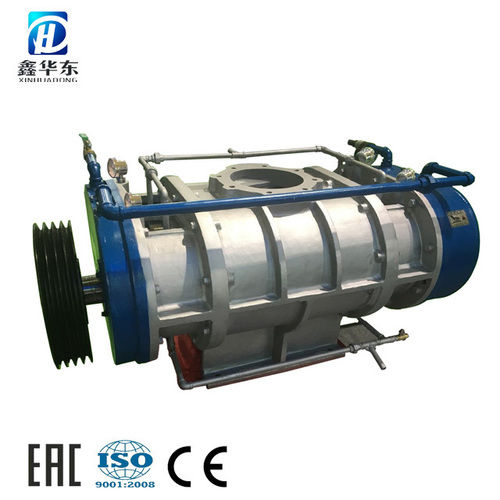

- HDSR-MJ 3 Lobe Compact Roots Blower

- Hot sale new design HDSR series three lobes roots blower for industrial use with IO9001 CE EAC certifications

- HDSR 3 Lobe Roots Blower

- HDR 2 Lobe Roots Blower

- HTR Double Stage Roots Blower

- HDLH 3 Lobe Roots Blower

- HG Tri Lobe Roots rotary lobe blower for wastewater aeration in sewage treatment plants

- Hot sale new design HDSR series three lobes roots blower for wastewater treatment

- High Efficiency Roots Vacuum Pump Energy Saving Blower Air Pressure Blower

- Roots vacuum pump

- Aquaculture Farm Aeration Blower

- Turbo Blower

- More Info

- Contact Us

Call Me Free

Call Me Free